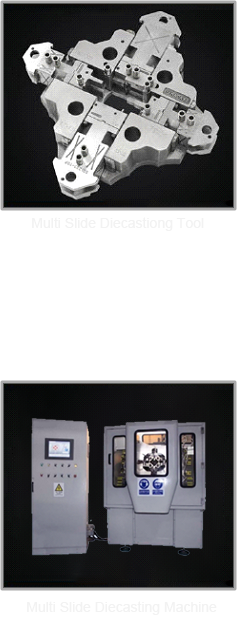

• A "multiple-slide" hot chamber die-casting machine has two or more(up to 6) independently movable slides, which carry die blocks and operate within a precision slide guiding system.

• The use of up to four slides is common, and as many as six slides are possible

• Each of the die blocks has one or more cavities and/or cores on its face, which together form the complete cavity and runner profile (into which the molten metal is injected).

• The mating faces of the die blocks are held together by a clamping system.

• Injection of molten metal is made perpendicular to the mating faces of the die blocks, directly on the parting line (“parting line injection”), thereby

The advantages of this technology include:

• Complex part geometry produced with high precision; Consistent part quality;

• Excellent part to part conformity

• Quick die changeovers; up to 75 cycles per minute (4,500 shots per hour). Rapid cycle speeds;

• In-die de-gating and automatic separation of parts from runners is possible in many cases;

• Flash-free castings;

• Low tooling costs;

• Elimination / reduction of secondary operations;

• Savings in material, energy & labor.